For Steel Mill Crane Buyers: Avoid Average Billet Mistakes

For Steel Mill Crane Buyers: Why Average Billet Weight Assumptions Are Dangerous

Most Important Takeaway

Crane buyers cannot simply rely on the average billet weight when choosing a steel mill crane or billet handling crane. Assuming average weights might seem convenient, but it’s risky. You could end up with overloads, mechanical damage, unexpected downtime, and even safety incidents in your workshop.

To select the right crane, you need to understand:

- Maximum load your crane will ever lift

- Bundle lifting scenarios

- Billet size variations

- Temperature effects, especially when handling hot billets

These factors determine not just safety, but also the long-term reliability and efficiency of your overhead crane system.

Key Takeaways & Questions Answered

Before finalizing any purchase, keep these points in mind:

- Maximum load is the true benchmark: Never assume that the average weight represents what your crane will actually lift. Always plan for the heaviest expected load.

- Bundle lifting and billet variations matter: Lifting multiple billets at once, or uneven lengths, can dramatically change load distribution and stress points.

- Hot billets change weight behavior: High-temperature billets can behave differently when gripped. They may shift, expand, or add dynamic forces that affect your crane’s hoist, girders, and clamps.

- Dynamic forces add to real load: Acceleration, deceleration, and lifting motion all increase the effective load on your crane beyond static calculations.

Questions this guide answers:

- What is the heaviest load my crane will ever lift?

- Are bundles, length variation, and scale included in load calculations?

- How do hot billets affect crane and clamp performance?

- How can I avoid crane overloads and unexpected downtime?

Why Average Billet Weight Is Misleading

Many crane buyers fall into the trap of designing a crane around the average billet weight. It might seem simple, but in practice, it’s far from safe. Here’s why:

- Peak loads often exceed averages: The occasional heavy billet, or a bundled lift, can exceed your calculated average. This puts extra stress on hoists, mechanical clamps, and bridge girders, sometimes beyond safe limits.

- Bundles, uneven lengths, and scale: Multiple billets lifted together can create a weight spike. Even small variations in billet length or surface scale can increase the real load significantly. For example, a bundle of five billets may weigh 20–30% more than expected if scale or uneven lengths are not considered.

- Hot billets behave differently: Temperature changes affect weight distribution, grip, and dynamic forces. Hot steel expands slightly and can move under clamps, creating shifting loads that a crane designed for average cold billet weight cannot safely handle.

Buyer tip: Always calculate the worst-case scenario, including maximum bundle size, billet length variations, surface scale, and temperature effects. This ensures your crane, whether a billet handling crane, overhead crane, or single/double girder crane, can safely handle real operating conditions.

clamp overhead crane for billets handling

Maximum Load vs. Average Load

Rated Capacity vs. Real Load

When selecting a steel mill crane or billet handling crane, understanding the difference between rated capacity and the real-world load is critical. The rated capacity is the maximum weight the crane can lift safely under ideal conditions. It’s what the manufacturer guarantees, usually tested under controlled environments.

But here’s the catch: average billet weight doesn’t reflect reality. In daily operation, cranes often lift uneven bundles, hot billets, or pieces with scale that add extra weight. If you base your crane selection on averages, you’re ignoring the peaks—the heaviest loads that actually stress the crane.

- Overloading can happen quickly, even if most lifts are below average.

- Mechanical clamps, hoists, and bridge girders experience stress beyond their design limits.

- Repeated exposure to these extremes accelerates wear and can lead to unexpected failures.

Practical tip: Always calculate for the heaviest load your crane might ever encounter, not the average. This approach avoids downtime and expensive repairs.

Safety Margins Are Limited

Manufacturers often include a safety margin, typically 20–30%, in their crane ratings. It sounds reassuring, but in real operations, these margins can be exceeded. A bundle of billets that’s slightly heavier than expected, combined with a hot temperature effect, may push the crane beyond its rated capacity.

- Safety margins are not infinite; they’re meant to cover minor variations, not major miscalculations.

- Ignoring bundle size, billet length variations, or thermal expansion can render the safety margin useless.

Buyer tip: Always plan for the worst-case scenario, including bundle lifting, irregular lengths, scale, and hot billets. This ensures your crane is reliable, safe, and performs consistently in real-world conditions.

Real-World Factors That Affect Crane Loads

Selecting a steel mill crane or billet handling crane isn’t just about rated capacity. The real load your crane experiences depends on several practical factors that buyers often overlook. Understanding these will help you avoid overloads, clamp failures, and costly downtime.

Bundle Lifting

Lifting multiple billets at once significantly increases the real load. For example, a single 150×150 mm billet weighs about 500 kg, but lifting a bundle of 5–6 billets increases the load to 2.5–3 tons, not including variations in billet length or scale.

Example Bundle Weights:

| Billet Size (mm) | Weight per Billet (kg) | Number of Billets in Bundle | Total Bundle Weight (kg) |

|---|---|---|---|

| 150×150×6 m | 500 | 3 | 1,500 |

| 150×150×6 m | 500 | 5 | 2,500 |

| 200×200×6 m | 900 | 4 | 3,600 |

| 200×200×6 m | 900 | 6 | 5,400 |

Practical Tips:

- Always plan for the heaviest possible bundle, not the average.

- Verify bundle lifting limits with suppliers to ensure hoists and clamps can handle the maximum expected load.

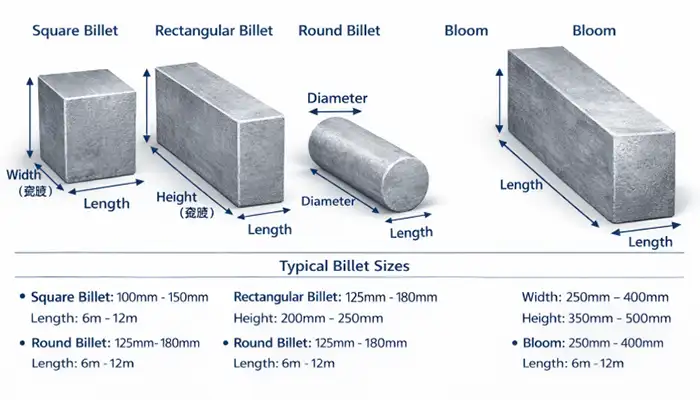

Length and Dimension Variations

Not all billets are uniform. Lengths may range from 4 m to 8 m, and widths from 150 mm to 200 mm, creating uneven load distribution. Irregular billets can shift the center of gravity, stressing clamps, hoists, and bridge girders unevenly.

Impact of Uneven Lengths:

| Bundle Composition | Longest Billet (m) | Shortest Billet (m) | Total Weight Variation (%) |

|---|---|---|---|

| 5 billets, 150×150 mm | 6 | 6 | 0 |

| 5 billets, 150×150 mm | 6.5 | 6 | +5 |

| 5 billets, 150×200 mm | 7 | 6 | +8 |

| 6 billets, 200×200 mm | 8 | 6 | +10 |

Practical Tips:

- Include the longest and heaviest billet dimensions in crane calculations.

- Uneven loads can increase dynamic forces by 10–15%, which should be accounted for in crane selection.

Surface Scale and Material Effects

Scale, rust, or surface oxidation adds extra weight. For example, a 6 m long, 150×150 mm billet may accumulate 20–25 kg of surface scale, and a bundle of 5 billets adds another 100–125 kg.

Effect of Scale on Bundle Weight:

| Billet Size (mm) | Number of Billets | Base Weight (kg) | Estimated Scale Weight (kg) | Total Bundle Weight (kg) |

|---|---|---|---|---|

| 150×150×6 m | 5 | 2,500 | 125 | 2,625 |

| 200×200×6 m | 4 | 3,600 | 100 | 3,700 |

| 200×200×6 m | 6 | 5,400 | 150 | 5,550 |

Practical Tips:

- Conduct on-site weight verification including scale, surface condition, and temperature effects.

- Ensure clamps and hoists can handle these extra unplanned kilograms.

Temperature and Hot Billets

Handling hot billets introduces another layer of complexity for steel mill crane buyers. Heat affects not only the weight behavior but also the dynamic forces on hoists, clamps, and bridge girders. Ignoring these factors can easily push a crane beyond its rated capacity.

How Hot Billets Affect Crane Loads

- Thermal expansion: Steel expands when hot, slightly increasing length and potentially shifting the center of gravity in bundles.

- Grip performance: Clamps may require more force to secure hot billets safely.

- Dynamic effects: Moving hot billets can cause additional forces due to slight swinging, tilting, or uneven expansion, which may add 5–10% extra load over the nominal weight.

Practical tip: Always factor in temperature-related load changes when selecting a crane or hoist. A crane rated for cold billets may be insufficient for the same bundle when handling hot billets at 800–1,200 °C.

Estimated Load Increase by Billet Temperature

| Billet Size (mm) | Weight per Billet (kg) | Temperature (°C) | Estimated Weight Shift / Dynamic Effect (%) | Effective Weight per Billet (kg) |

|---|---|---|---|---|

| 150×150×6 m | 500 | 25 (cold) | 0% | 500 |

| 150×150×6 m | 500 | 800 | +5% | 525 |

| 150×150×6 m | 500 | 1,000 | +7% | 535 |

| 200×200×6 m | 900 | 25 (cold) | 0% | 900 |

| 200×200×6 m | 900 | 1,000 | +10% | 990 |

Key Insights:

- Even a 5–10% increase per billet can push a multi-billet bundle beyond the crane’s rated load.

- Hot billet handling affects not only hoist and clamp performance but also bridge girder stress and crane stability.

Buyer Tips for Hot Billet Handling

- Include the maximum operating temperature of billets in crane specifications.

- Verify that clamps, hoists, and bridge structures can handle the extra weight and dynamic forces.

- Consider adding a temperature factor (5–10%) to calculated bundle weights for safety.

- Always plan for worst-case scenarios, including combined effects of bundles, uneven lengths, surface scale, and hot temperature.

Crane Buyer Checklist

When buying a steel mill crane or billet handling crane, asking the right questions upfront can save you significant costs and prevent safety issues later. Many buyers focus on the crane’s rated capacity alone, assuming it will handle all loads. In reality, the real operating load often exceeds averages due to factors like bundle lifting, billet size variations, surface scale, and hot temperature effects.

Using a structured checklist helps buyers ensure the crane can handle maximum expected loads safely and reliably. It also provides a clear framework for discussion with suppliers and engineers, reducing misunderstandings that lead to overloads or mechanical failures.

What is the heaviest single load my crane will lift?

Before finalizing a crane purchase, it’s crucial to identify the maximum load the crane will ever encounter. Don’t rely on averages. For example, a single billet might weigh 500 kg, but a bundle of 5 billets can reach 2,500–3,000 kg, not including temperature effects or surface scale.

Additionally, the rated capacity of the crane must include a safety margin, typically 20–30%, to cover minor variations. Without considering the heaviest single load plus safety margin, you risk stressing hoists, clamps, and girders.

Example Table – Maximum Single Load:

| Parameter | Value / Notes |

|---|---|

| Single Billet Size (mm) | 150×150×6 m |

| Weight per Billet (kg) | 500 |

| Number in Bundle | 5 |

| Total Bundle Weight (kg) | 2,500 |

| Safety Margin (%) | 20–30 |

| Effective Crane Load (kg) | 3,000 |

Are bundle lifting and length variations included in calculations?

Crane buyers often underestimate the impact of bundle lifting. Multiple billets lifted together create uneven load distribution, especially if lengths or cross-sections vary. Even small differences in size or weight can create dynamic effects, which may add 5–15% to the nominal load.

Consider a bundle where one billet is 0.5 m longer than the others. The center of gravity shifts, increasing stress on clamps and the bridge girder. Such variations are easy to overlook if calculations only consider average weights.

Table – Bundle and Length Variations Impact:

| Factor | Typical Effect on Load |

|---|---|

| Bundle size (number of billets) | +500–1,500 kg depending on size |

| Billet length variation | +5–10% dynamic effect |

| Uneven width or cross-section | Potential shift in center of gravity |

Practical tip: Always include the longest and heaviest billets in bundle calculations and verify crane specifications can handle these extremes.

How do surface scale or billet impurities affect weight?

Steel billets often have scale, rust, or surface oxidation that add unexpected weight. For example, a 6 m long, 150×150 mm billet may carry 20–25 kg of surface scale, which adds up to 100–125 kg for a 5-billet bundle. Ignoring this factor can affect clamp grip, create uneven load, and increase dynamic stress during lifting.

Table – Effect of Surface Scale on Bundle Weight:

| Billet Size (mm) | Number of Billets | Base Weight (kg) | Estimated Scale (kg) | Effective Load (kg) |

|---|---|---|---|---|

| 150×150×6 m | 5 | 2,500 | 125 | 2,625 |

| 200×200×6 m | 4 | 3,600 | 100 | 3,700 |

Buyer tip: Conduct on-site verification of billet weights and surface conditions to ensure the crane can safely handle the additional load.

Are hot billets considered in hoist and clamp design?

Handling hot billets introduces thermal expansion and dynamic effects. Steel expands slightly when heated, shifting the center of gravity in a bundle. Hot billets can also swing more under clamps, which may increase dynamic forces by 5–10% beyond nominal weight.

Table – Effect of Temperature on Crane Load:

| Billet Size (mm) | Base Weight (kg) | Temperature (°C) | Dynamic Effect (%) | Effective Weight (kg) |

|---|---|---|---|---|

| 150×150×6 m | 500 | 800 | +5% | 525 |

| 150×150×6 m | 500 | 1,000 | +7% | 535 |

Practical tip: Ensure that hoists, clamps, and bridge structures are rated for maximum expected temperature effects, including dynamic load increases.

Are dynamic forces during lifting and motion accounted for?

Even a crane rated for the correct static load can experience higher forces in real operation. Acceleration, deceleration, and bundle swinging can add 5–15% to effective load. These dynamic forces must be considered in crane selection and hoist design.

Table – Dynamic Force Impact:

| Factor | Load Increase (%) | Notes |

|---|---|---|

| Acceleration / Deceleration | 3–5 | Frequent starts and stops |

| Bundle swinging | 5–10 | Uneven or long billets |

| Clamp gripping variation | 2–3 | Hot billets or surface irregularities |

Buyer tip: Always include dynamic effects when calculating maximum load. Factor these into hoist, clamp, and bridge design specifications.

Consequences of Underestimating Load

Underestimating the real load a crane will handle is one of the most common mistakes steel mill crane buyers make. Surprisingly, many crane failures are not caused by poor equipment quality, but by buyers relying on average weights instead of maximum loads. Ignoring real-world factors like bundles, length variations, surface scale, or hot billets can quickly push a crane beyond its rated capacity.

Mechanical Failures and Overload Risks

Hoists, clamps, and bridge girders are designed for maximum rated loads. Lifting bundles or hot billets that exceed these limits can cause immediate mechanical stress, leading to:

- Wire rope or chain damage

- Clamp deformation

- Bridge girder bending or structural fatigue

Example: A crane rated for 10 tons lifting average billets may fail if a bundle of 5 hot billets at 1,050 kg each is lifted simultaneously. The real load becomes 5.25 tons, plus dynamic forces, exceeding safety limits.

Production Downtime and Repair Costs

- When a crane fails due to overload, downtime can halt production for hours or even days, depending on the severity of the damage.

- Emergency repairs or component replacement can be costly, particularly for wire ropes, hoists, or mechanical clamps.

- Redesigning the crane to handle underestimated loads may require structural modifications, adding further expense.

Safety Hazards

Overloading a crane increases the risk of accidents, including:

- Dropped billets or bundles

- Swinging loads striking personnel or equipment

- Clamp slippage or failure

Even experienced operators cannot fully compensate for a crane operating beyond its limits. Planning for maximum loads is the only reliable way to prevent safety incidents.

How to Prevent These Consequences

To avoid crane overloads, downtime, and safety hazards:

- Always design and select cranes based on the heaviest expected load, not the average.

- Include factors like bundle size, billet length variations, surface scale, and hot temperature effects.

- Factor in dynamic forces during lifting, acceleration, and deceleration.

- Verify that hoists, clamps, and bridge structures are rated for real-world maximum loads.

Table – Real vs. Underestimated Load Impact:

| Scenario | Calculated Average Load (kg) | Real Load Including Factors (kg) | Potential Risk |

|---|---|---|---|

| Single billet 150×150×6 m | 500 | 500 | Low risk |

| 5-billet bundle, cold | 2,500 | 2,625 | Minor overload |

| 5-billet bundle, hot, dynamic forces | 2,500 | 2,850–3,000 | High risk – clamp and hoist stress |

| 6-billet bundle, uneven length | 3,000 | 3,450–3,600 | Very high risk – potential failure |

Buyer Takeaways:

- Crane failures are often preventable with accurate load planning.

- Avoid average weight assumptions—they hide the real stress on cranes.

- Proper maximum load calculations protect personnel, equipment, and production efficiency.

Practical Tips for Buyers

Choosing the right steel mill crane or billet handling crane goes far beyond simply checking the rated capacity. Many buyers make the mistake of assuming that average weights reflect actual operating conditions. In real steel mill operations, the heaviest loads, uneven bundles, hot billets, and dynamic forces determine how well a crane performs. Ignoring these factors can result in overloads, mechanical failures, downtime, and even safety hazards.

A structured approach to crane selection ensures that your investment is reliable, safe, and efficient. These practical tips focus on what crane buyers should consider when specifying equipment for real-world steel handling.

Always Use Worst-Case Scenario Calculations

Average billet weights can be misleading. A single 150×150 mm billet may weigh around 500 kg, but lifting a bundle of 5–6 billets can push the load to 2,500–3,000 kg. Add dynamic forces, hot temperature effects, and surface scale, and the real load may be significantly higher than anticipated.

Planning for the worst-case scenario ensures the crane, hoist, clamps, and bridge structures are all designed to handle maximum expected loads safely. It also provides a clear margin for unpredictable variations in steel handling operations.

Example Table – Worst-Case Load Planning:

| Parameter | Average Calculation (kg) | Worst-Case Scenario (kg) | Safety Margin (%) | Effective Design Load (kg) |

|---|---|---|---|---|

| Single billet 150×150×6 m | 500 | 500 | 20 | 600 |

| 5-billet bundle, cold | 2,500 | 2,625 | 25 | 3,280 |

| 5-billet bundle, hot + dynamic | 2,500 | 2,850–3,000 | 25 | 3,562–3,750 |

Practical Tip: Always calculate maximum bundle weight plus dynamic and thermal effects when selecting cranes and hoists.

Include Bundles, Billet Length Variation, Scale, and Temperature Effects

Crane buyers often overlook the combined effects of bundle lifting, billet length variations, surface scale, and hot temperatures. These factors directly affect how the crane performs under real-world conditions.

- Bundle Lifting: Multiple billets lifted together create higher loads and uneven distribution.

- Length Variations: Billets that differ in length or cross-section shift the center of gravity and increase dynamic stress on clamps and girders.

- Surface Scale: Even minor surface oxidation or impurities can add extra kilograms per billet.

- Temperature Effects: Hot billets expand slightly and behave differently, which may increase swinging or uneven gripping, adding 5–10% extra load.

Buyer Tip: Collect detailed operational data, including bundle sizes, billet dimensions, temperature ranges, and surface conditions, and provide it to your supplier to ensure accurate crane specification.

Validate Crane Specifications with Third-Party Engineering Review

Even when a supplier provides rated load data, a third-party engineering review is highly recommended. Independent verification ensures that hoists, clamps, bridge girders, and control systems are all rated for real-world conditions, including maximum loads, temperature effects, and dynamic forces.

Table – Recommended Validation Checklist:

| Component | Review Focus |

|---|---|

| Hoist | Rated capacity, overload tolerance |

| Clamp | Grip performance, hot billet handling |

| Bridge girder | Structural strength, deflection limits |

| Control system | Load monitoring, emergency stop accuracy |

Factor in Dynamic Loads from Lifting, Acceleration, and Stopping

Crane operation is rarely static. Even if the nominal load is within specifications, dynamic forces caused by acceleration, deceleration, swinging bundles, or uneven gripping can increase the effective load by 5–15%.

- Lifting long or uneven bundles can cause tilting or shifting.

- Sudden starts and stops amplify forces on hoists, clamps, and bridge structures.

- Temperature effects and surface irregularities further compound the dynamic load.

Table – Dynamic Load Factors:

| Motion Type | Load Increase (%) | Notes |

|---|---|---|

| Acceleration / deceleration | 3–5 | Short travel distances, frequent stops |

| Bundle swinging | 5–10 | Uneven or long billets |

| Clamp grip variations | 2–3 | Hot billets or surface irregularities |

Key Buyer Takeaways:

- Always plan for worst-case loads, not averages.

- Document bundle size, billet length, surface scale, and temperature conditions.

- Use third-party engineering validation to verify crane specifications.

- Factor in dynamic forces caused by lifting, motion, and operational variations.

- Following these steps reduces the risk of overloads, downtime, and safety incidents.

Conclusion

For steel mill crane buyers, assuming that average billet weight represents the real operating load is a common and costly mistake. Many crane failures, overloads, and unexpected downtime happen not because of poor equipment quality, but because buyers underestimated the maximum load their crane would experience.

By carefully considering maximum load, bundle lifting, billet size and length variations, surface scale, hot billet effects, and dynamic forces, buyers can make informed decisions that protect both personnel and production. Proper planning ensures that cranes operate safely, efficiently, and reliably over their full service life.

Key Takeaways for Buyers

- Prevent Crane Overloads and Mechanical Failures: Always design cranes for the heaviest expected load, including dynamic and thermal factors.

- Ensure Safety for Personnel and Equipment: Factoring in real-world conditions reduces the risk of dropped billets, clamp failures, and structural stress.

- Avoid Costly Redesigns, Downtime, and Production Losses: Correct specifications upfront prevent emergency repairs, structural modifications, and production interruptions.

Final Takeaway:

The real load, not the average, determines the safety, reliability, and longevity of your steel mill or billet handling crane. Always plan, design, and purchase with the heaviest possible scenario in mind. Taking this approach ensures your crane performs as expected under the most demanding operating conditions, protecting your investment, personnel, and production efficiency.